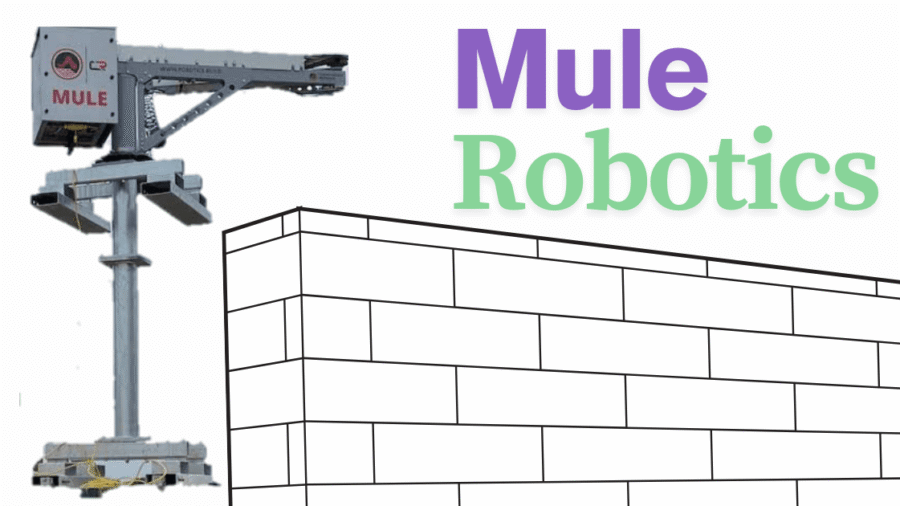

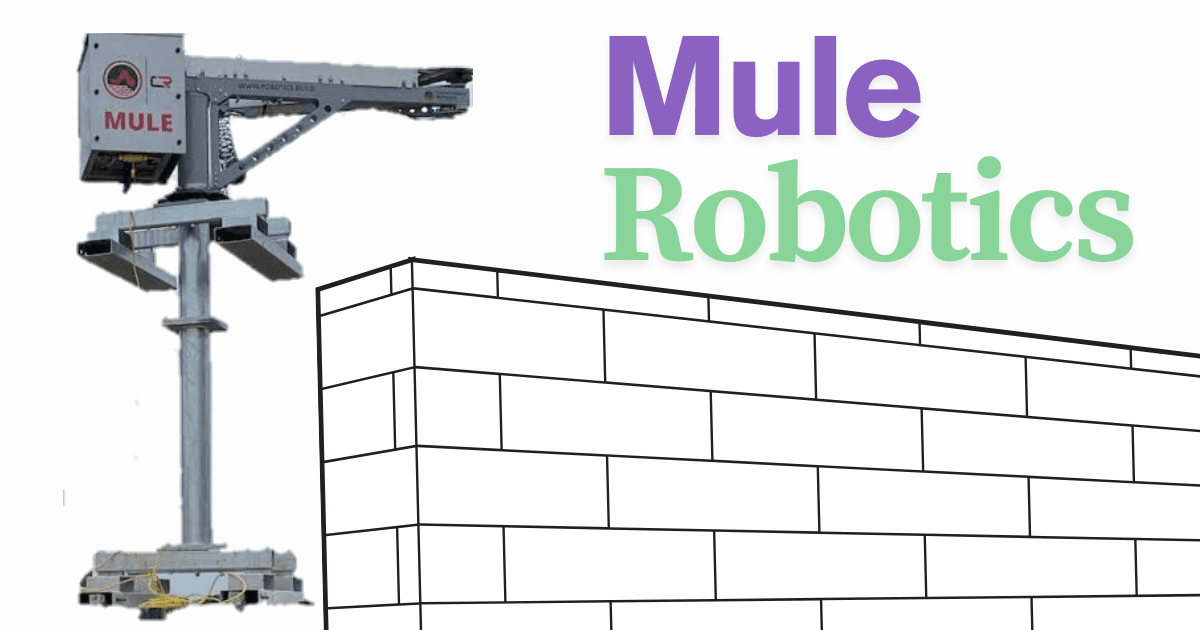

What is Mule Robotics?

At its core, Mule Robotics is a class of intelligent robotic systems

designed to augment human capabilities in heavy material handling,

particularly in construction and industrial settings. The term “MULE”

stands for Material Unit Lift Enhancer, and these systems are purpose built to assist with the lifting and positioning of large, heavy

construction blocks, especially concrete masonry units (CMUs).

The Rise of Mule Robotics in Construction the rapidly evolving world of construction, innovation isn’t just a buzz word—it’s a necessity. Labor shortages, rising project demands,and the physical toll on workers are pushing the industry toward smarter,more sustainable practices. Mule Robotics has emerged as atransformative force in this domain. Whether it’s lifting heavy blocks orautomating repetitive lifting tasks, Mule Robotics—through systems like the concrete mule, mule robot, and mule lift—is redefining what’spossible on the job site.

Key variants include:

Concrete Mule: Specializes in handling heavy concrete blocks.

Mule Robot: A robotic arm integrated with lifting assistance and

AI.

Mule Lift: A vertical lifting mechanism that works in sync with

construction teams.

Whether you’re operating on a small residential project or a massive

commercial build, Mule Robotics allows workers to do more, lift

smarter, and reduce fatigue-related injuries.

The Technology Behind Mule Robotics

What makes Mule Robotics so effective? It’s a sophisticated

combination of robotics, ergonomic engineering, and AI-enhanced

control systems. Let’s break it down:

- Robotic Arm Precision: The mule robot is built with precision

motors and sensors to detect weight distribution, grip strength, and

optimal placement angles. - AI Integration: Some mule lift models are integrated with

adaptive software that learns usage patterns and adjusts assistance

accordingly. - Operator Control: Despite being autonomous, Mule Robotics

systems often include manual override features, allowing workers

to guide movement with ease.

These technologies work in harmony to improve not only speed but also

safety, making Mule Robotics one of the most reliable co-workers you

can add to your team.

The Benefits of Mule Robotics in the Field

Why is Mule Robotics gaining such momentum? Let’s explore its top

benefits:

Injury Reduction

Musculoskeletal injuries are the most common hazard in construction.

With Mule Robotics, workers experience less strain on the back,

shoulders, and knees. A mule lift takes the weight off the human body,

redistributing it through its mechanical arms.

Labor Optimization

With fewer skilled masons available, contractors are under pressure.

Mule Robotics helps teams complete heavy lifting tasks faster and with

fewer people. This not only addresses labor shortages but enhances

productivity across the board.

Precision and Quality

The concrete mule delivers a consistent, accurate block placement,

leading to cleaner lines, better alignment, and higher structural integrity.

Scalability

Whether you rent a single mule robot or equip a fleet of them across

sites, the technology scales to match your project’s size and scope.

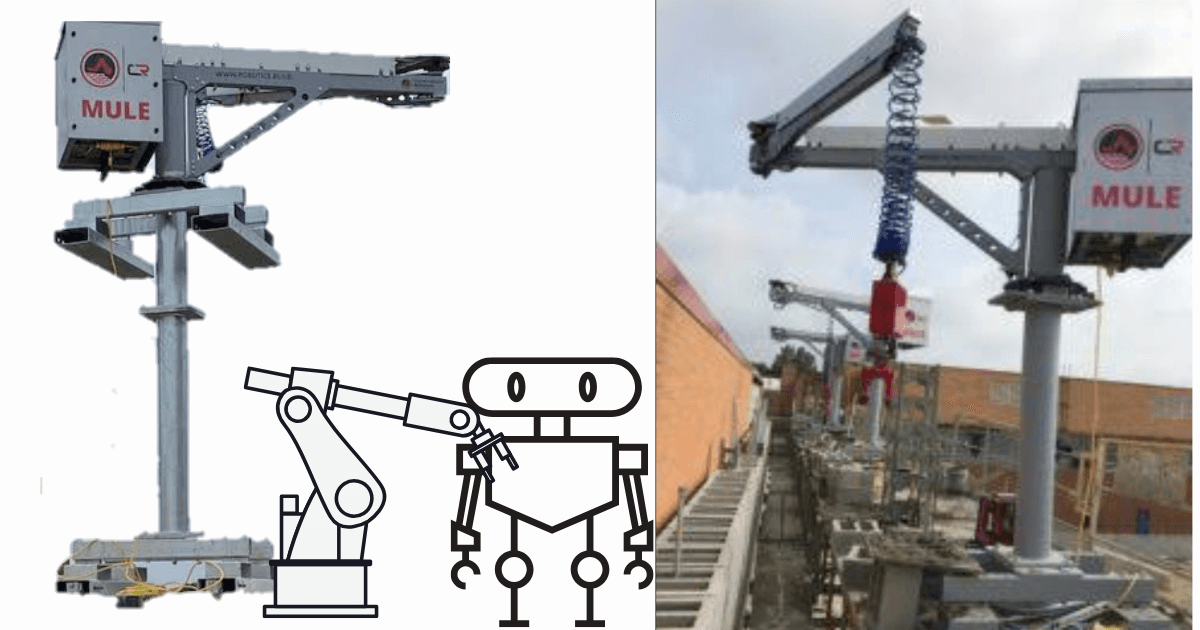

Concrete Mule: A Game-Changer in Masonry

Of all the tools under the Mule Robotics umbrella, the concrete mule

stands out for its industry-changing impact. Designed to lift and place

CMUs weighing up to 135 pounds, it allows a single worker to

accomplish what would traditionally require two or more.

Use Case Example:

On a typical site, a mason can place 90–110 CMUs per day. With a

concrete mule, that number can jump to 200+, effectively doubling

productivity while reducing injury risk.

Field Test Results:

According to data from Construction Robotics, projects that utilized the

concrete mule saw:

- 30% reduction in labor costs

- 50% increase in daily output

- 60% lower fatigue levels reported by workers

In short, the concrete mule is not just an assistant—it’s a competitive

advantage.

Mule Lift: Vertical Lifting Made Easy

A newer innovation in the Mule Robotics line is the mule lift, designed

for vertical material placement and precise alignment at various heights.

It features an extendable boom and smart positioning tech that keeps

blocks perfectly aligned even on uneven terrain.

Advantages of the Mule Lift:

- Perfect for high wall construction

- Easily transported across floors

- Can lift loads up to 150 lbs with zero swing or shift

The mule lift is revolutionizing how masons think about scaffolding,

reach, and height work—replacing risk with reliability.

Should we Rent a Mule? The Business Logic

You don’t always have to buy to reap the benefits. Many contractors

now rent a mule to minimize upfront investment. Here’s why that

makes business sense:

- Short-term flexibility: Try before committing long-term.

- Budget-friendly: Lower operational cost, no maintenance burden.

- Training included: Most rental services include basic training and support.

Top providers like Construction Robotics and MULE Rentals USA offer

flexible rental packages, allowing teams to rent a mule for a few days

or several months depending on project duration.

Real-World Case Studies: Mule Robotics in Action

To truly understand the power of Mule Robotics, we need to look at

real-world applications where these systems have delivered tangible

results. From skyscraper projects to school buildings and infrastructure

works, the mule robot is proving itself across sectors.

Case Study 1: Large-Scale Commercial Construction

In a high-rise construction project in Atlanta, Georgia, contractors

deployed 10 concrete mule units. The goal was to improve efficiency

and reduce labor dependence amid workforce shortages. The result?

- Daily block placement increased by 60%

- Labor costs dropped by 32%

- Worker compensation claims related to strain injuries fell to zero

The success led the company to rent a mule for all its ongoing builds

across the southeast region.

Case Study 2: School Expansion Project in Texas

A school district in Austin needed to expand two campuses in under six

months. Tight timelines and budget concerns made the use of mule lift

and mule robot technology a no-brainer.

- Crews lifted over 2,500 concrete blocks weekly

- Wall alignment accuracy exceeded 98%

- Completion time was cut by 28 days

In exit interviews, 87% of the workers said they would prefer using

Mule Robotics in future builds.

Mule Robotics vs. Traditional Labor: A Cost-Benefit Analysis

Metric

- Block Placement Rate

- Worker Fatigue

- Injury Risk

- Labor Needed

- Long-Term ROI

Traditional Labor

- 100-120/day

- High

- High (repetitive strain)

- 2-3 masons

- Limited

Mule Robotics

- 200-300/day

- Low

- Very Low

- 1 mason + mule

- High

Even when you rent a mule, your cost per square foot of masonry drops

significantly—especially when you account for fewer breaks, higher

accuracy, and near-zero rework rates.

Environmental and Sustainability Factors

In today’s eco-conscious world, the environmental impact of

construction tools and systems cannot be ignored. Here’s how Mule

Robotics aligns with sustainability goals:

Reduced Material Waste

With precise handling, concrete mule systems ensure accurate block

placements, reducing cracked or broken units.

Energy Efficiency

Modern mule robots are battery-operated and consume minimal power.

Unlike diesel-powered cranes or lifts, they produce zero emissions onsite.

Extended Career Lifespan for Workers

Less physical strain means that skilled workers can stay on the job

longer, reducing the turnover rate and improving overall workforce

sustainability.

Future of Mule Robotics: What’s Next?

The current generation of Mule Robotics has set a high benchmark, but

this is only the beginning. Here’s what we can expect in the near future:

AI-Driven Site Coordination

Imagine a network of mule robots working in sync with cranes, drones,

and autonomous forklifts. Integrated AI will allow Mule units to

communicate and coordinate with other smart devices for fully

automated workflows.

Advanced Material Handling

New models of mule lift are expected to handle not just CMUs but also

steel plates, timber panels, and prefabricated wall segments. This would

make Mule Robotics a central fixture across multiple trades.

Augmented Reality Integration

Masons wearing AR glasses could visualize exactly where to place each

block, while the mule robot positions it with surgical precision. This

fusion of physical and digital could be a game-changer.

Training & Adoption: How to Get Started with Mule Robotics

Worried about the learning curve? Don’t be. Mule Robotics is designed

for quick adoption:

- Training Time: Most workers become fully proficient in under 4 hours

- Support: Companies that rent a mule usually offer on-site support and maintenance

- Customization: Systems can be adapted for different block sizes and site layouts

Whether you’re a small contractor or a large developer, integrating Mule

Robotics can be as simple as scheduling a demo and booking your first

mule lift rental.

Mule Robotics: Revolutionizing Worksite Culture

One often overlooked benefit of Mule Robotics is the cultural shift it

brings to construction sites. Traditionally, masonry is known for being

labor-intensive and physically taxing. With Mule Robotics, that

perception is changing.

- Inclusivity: More women and older workers are joining the masonry field thanks to reduced lifting demands.

- Morale Boost: When workers see their productivity skyrocket without wearing themselves down, job satisfaction soars.

- Retention: Companies that use mule robots report higher retention rates and improved team dynamics.

These human-centered benefits are as valuable as the economic ones,

proving that Mule Robotics is about more than just machines—it’s

about making construction a more humane and future-ready industry.

Where to Rent a Mule Robot Today

If you’re ready to explore Mule Robotics for your next project, several

providers offer flexible rental options:

- Construction Robotics: Pioneers of the MULE system, offering nationwide rentals.

- Mule Rentals USA: Specializing in short-term and long-term contracts.

- Local Equipment Suppliers: Many regional suppliers now include concrete mule and mule lift systems in their offerings.

Costs vary based on location, duration, and quantity, but average pricing

ranges from $200–$300/day with training included.

Conclusion: Why Mule Robotics is the Future of Construction

After more than five decades of observing technological evolution

across construction, I can say without hesitation: Mule Robotics is one

of the most impactful developments of the 21st century.

From the rugged durability of the concrete mule, to the adaptability of

the mule lift, and the precision of the mule robot, these systems aren’t

just tools—they’re teammates. They lift more than blocks; they lift the

entire standard of modern masonry.

And whether you’re a construction veteran or a startup builder, the

decision to rent a mule could be your smartest investment yet.

Embrace the change. Empower your team. Let Mule Robotics do the

heavy lifting—literally and figurative.

read more:

Robot Cart : Amazing Tool To Transform Industries In 2024.

Germanium Transistor: Loaded with Mesmerizing features for 21st century.

How do drone shows work? It’s Cost and technology behind this wonder.

What is the future of RPA developer? : Robotic Process Automation in 2025

RUST : BEST LANGUAGE FOR ROBOTICS in 2025?

10 Reasons Why I Love Robotics

The Future of AI: Top 7 Latest AI developments

What is Mule Robotics and what is its primary function?

Mule Robotics refers to robotic systems designed to function like a mechanical pack mule capable of transporting heavy loads across rough or remote terrain. These robots are primarily used in military, agriculture, and industrial logistics to support humans by reducing physical burden and increasing efficiency in transporting goods.

Where are Mule Robots currently being deployed?

Military missions for carrying supplies and ammunition, Farms for transporting tools, crops, or feed across fields.

Disaster zones to deliver aid, medical supplies, or equipment in areas inaccessible to

humans or vehicles. Construction sites where material movement can be automated.

What technologies power modern Mule Robotics systems?

Modern Mule Robots are powered by:

AI and machine learning for route planning and obstacle detection

GPS and LIDAR for autonomous navigation

Sensor arrays for real-time feedback and environment interaction

What are the advantages of using Mule Robotics in critical missions?

Reduced human workload and risk, (especially in hostile environments)

High payload capacity, Terrain adaptability (from rocky slopes to muddy fields) Reliability(often with robust design for long-term use) are some advantages of mule robotics in critical missions.